CPP’s New HydraStop Hydraulic Assist Systems & Bare Units for 1974-86 CJ Series Jeep

Classic Performance Products, Inc. is now offering high-quality direct bolt-in hydraulic assist kits for 1974-1986 CJ series Jeeps. With larger, heavier tires and engine swaps becoming commonplace on classic Jeep CJs, a better and safer braking solution is needed. HydraStop for Jeep CJ was our answer.

Related Article: Upgrading Twitch’s 1966 C10 with CPP Big Brakes and HydraStop

CPP’s HydraStop kits are designed to replace manual or vacuum-assisted brakes with a powerful and compact modern hydraulic assist unit. These are the perfect upgrade for large cam and low vacuum applications or whenever greater braking pressure is required. These HydraStop™ systems include everything you need to install in an afternoon using common hand tools and average mechanical skills.

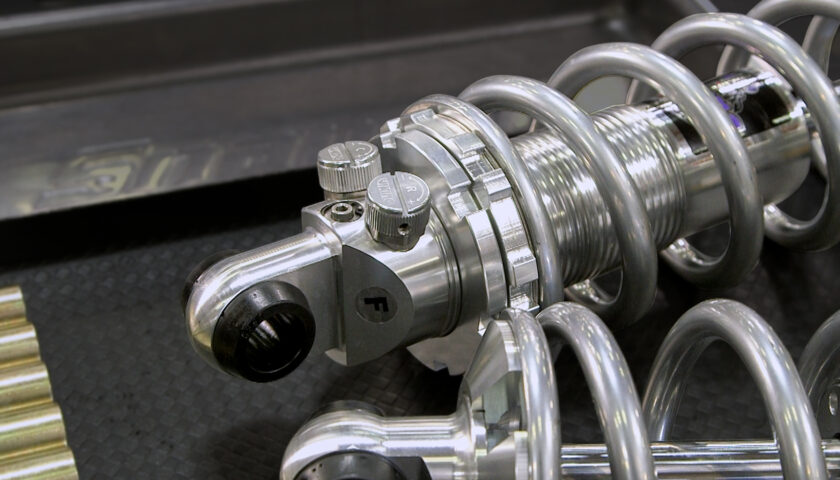

All CPP kits include a direct-fit, high performance hydraulic brake assist unit that uses all new parts and puts out an amazing 1800psi at the wheels. The HydraStop™ Assist System for CJ Series Jeep are available in three different kits: the Street Beast package with steel firewall mounting bracket, aluminum Corvette-style master cylinder, side mounted Prop & Stop Block Kit, and rubber hoses; Black Wilwood Kit with upgraded Wilwood Master Cylinder and Wilwood proportioning valve plus billet aluminum mounting bracket; and a basic Street Beast kit which includes all the hydraulic components and can be paired with any GM 1-1/8” bore master cylinder. Kits include all necessary fittings and hardware for installation.

Check out the video above to watch Jason Scudellari install one of our HydraStop kits on a modified Jeep CJ7!

#7486HBK 1974-1986 Jeep CJ-Series HydraStop Instructions

1. Begin by installing the HydraStop Unit to the firewall using the provided hardware (Shown is a pre-production unit; the final version will have studs installed on the mounting bracket and will be secured with nuts on the inside of the firewall).

2. Bench bleed the master cylinder using CPP’s Master Cylinder Bleeder Kit #CPP-BK before installing it in the Jeep.

3. Install the master cylinder to the HydraStop unit then attach the brake lines to the master cylinder.

Related Video: How to Bench Bleed a Master Cylinder

4. Convert the power steering box and power steering pump to -6AN using the provided adapter fittings.

5. Plan out the hose routing before beginning to assembling the high and low pressure hoses, making sure to there is plenty of space between any moving parts or hot exhaust.

6. To install the high pressure hoses, begin by twisting the nut, which has left handed threads, on to the braided hose.

7. Then attach the fitting, which has right handed threads, to the nut. Make sure to clock the fittings in the desired orientation because the hoses do not twist. Once the desired length has been chosen, cut the braided hose and make sure to thoroughly clean out the hose of any debris.

8. Then assemble the low pressure side using the supplied push lock hose and fittings. Installing an inline filter (#PSF-AN) is cheap insurance to protect your HydraStop and power steering system.

9. There is an option for either a barbed T-fitting (included) or an -6AN Y fitting (#CP6ANM-Y) when routing the low pressure side into the power steering system.

10. Proceed to tighten all fittings on the HydraStop system, power steering pump and steering box.

11. Connect the pushrod on the HydraStop to the brake pedal under the dash. When adjusting the pushrod length, make sure to avoid preloading the HydraStop.

12. To bleed the system, we suggest lifting the front tires off the ground then, with the vehicle running, turn the steering from lock to lock until there are no bubbles in the system. Make sure to use new, high quality power steering fluid like ACDelco to keep your system running smoothly.

Installation Note: Some early year CJ series Jeeps may require drilling new holes in the firewall to accommodate the HydraStop unit. Refer to the included drawing for measurements. The studs in the HydraStop bracket may be removed and the bracket can be used as a template to mark the location for the holes.