We decided to answer the question, “are tubular control arms worth it?” by showing you rather than just telling you. Check out the video below to learn some of the benefits of going with CPP Totally Tubular arms.

So, are tubular control arms worth it after all? Unless your goal is to do a factory restoration on your classic car or truck, upgrading to tubular control arms is a no-brainer.

Why Choose CPP Totally Tubular

CPP’s Tubular Control Arms are designed to provide full wheel travel with minimal friction. The control arms are made from thick D.O.M. tubing . Also, the lower arms provide increased ground clearance and allow the use of sway bars. They can be installed with either factory uppers and lowers, or as a full set.

The bushings are made from self-lubricating, non-squeak PolyPlus bushings. They will outlast any rubber or urethane and work at temperatures in excess of 400 degrees F.

Related Story: Building a Restomod Tri-Five Chassis with all CPP Parts

The Chrome-moly cross shafts and sleeves are zinc plated for lasting performance. As an added safety feature, the sleeves have an interlocking design that prevents the hardware from ever working loose. This design also means there is virtually zero flex during hard cornering.

CPP control arm assemblies are a simple bolt-in installation with no modification required. They are designed to work with all factory and replacement power steering systems, with or without O.E. bump stops and with big brake kits.

Benefits of Tubular Control Arms from CPP

- Allow full wheel travel

- Low friction, self-lubricated bushings

- Precision welded using D.O.M. tubing for maximum strength

- Virtually zero flex during hard cornering

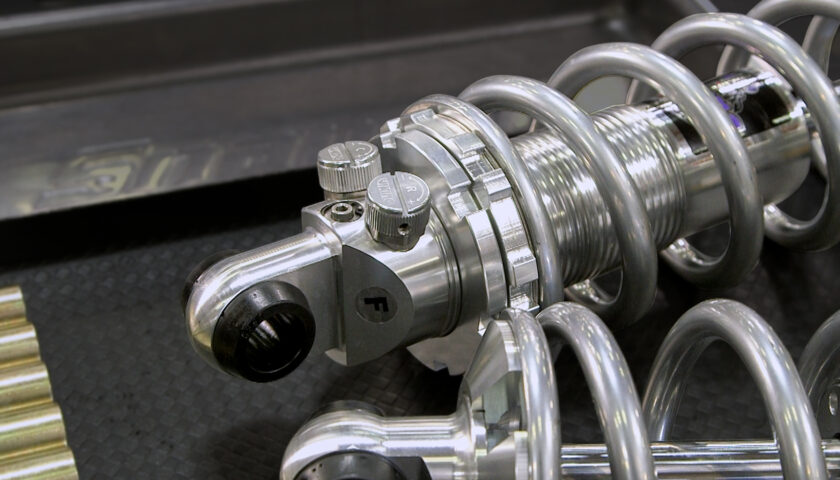

- Works with popular upgrades like sway bars, big brakes, coilovers and air bags

- Interlocking cross shaft design for added safety

- True bolt-in installation