Want to see more of this 1985 C10 and our other builds? Check Out Our Other Projects Here

For this Week To Wicked build, Classic Trucks Magazine and LMC Truck started with a stock 1985 C10. The goal was to transform it into one clean custom Square Body Chevy in only five days!

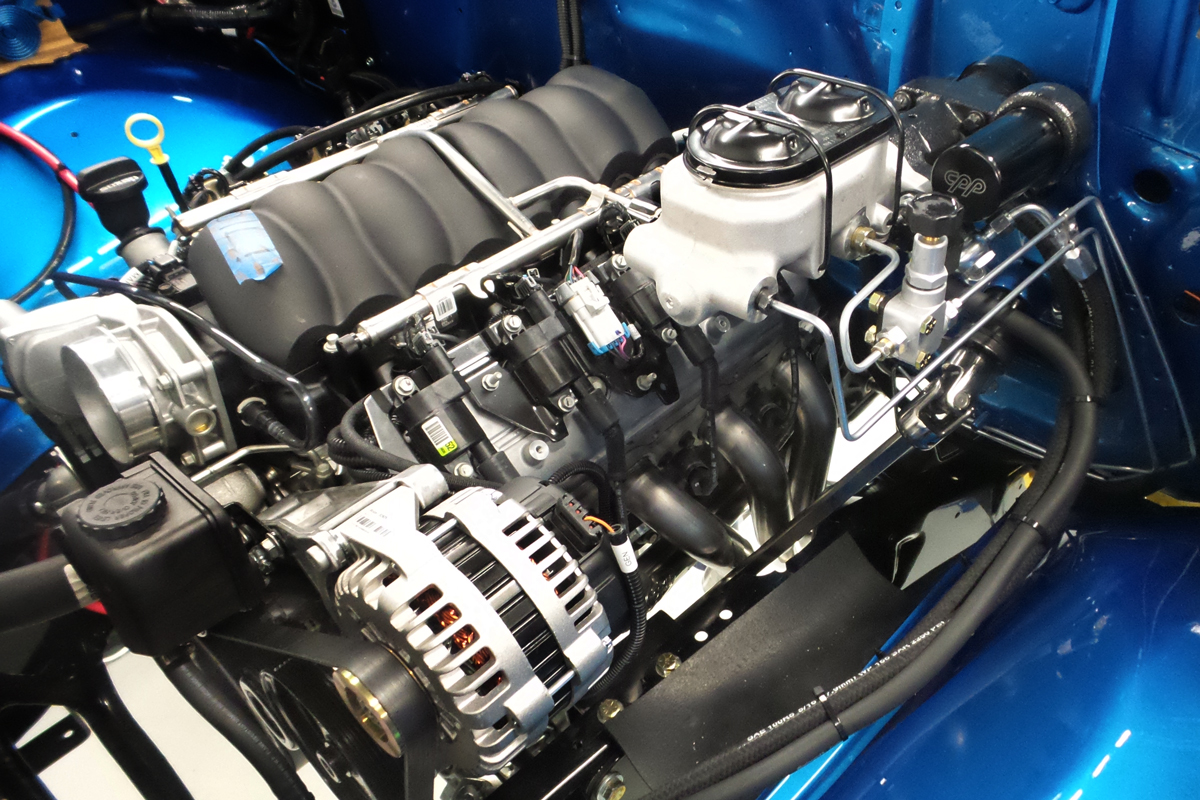

And transform it they did. The crew sharpened all the corners of this old “square.” They touched everything from suspension to a 525 horsepower LS engine. Classic Performance Products, Inc. (CPP) stepped in to assist the crew by adding all-new braking performance to the C10. That was thanks to a complete front & rear CPP Performance Brake Kit and HydraStop Hydraulic Assist Street Beast System. A CPP Classic Fit Tilt Steering Column and a billet aluminum steering wheel added a touch of class to the interior.

Related Story: 1971 C10 Week To Wicked: Building a Short Bed Chevy To Die For

This special C10, was featured on display at the SEMA Show in Las Vegas. The keys were then handed over to one lucky winner during the first ever C10 Nationals in May 2018!

Day One

The plan for Day 1 was straightforward: remove the old and install the new as quickly as possible! The C10’s underpinnings were pulled out in no time. Preparations were then made for installing a bolt-in IFS and four-link rear, each outfitted with adjustable coilovers and CPP disc brakes. An upgraded Connect & Cruise LS376 backed by a 4L65E overdrive transmission was installed in place of that original 305ci small-block. Finally, power will be sent to the 9-inch rearend.

Day Two

The Square Body Chevy progressed as the CPP crew started Day 2. They began by installing the crossed-drilled and slotted CPP Performance Brake Kit for Mustang II to the front spindles. A CPP 12″ Rear Big Brake Kit was then fitted to the 9-inch rearend. New brake lines and plumbing were bent and ran while the Hydrastop Hydraulic Assist Street Beast System was cleanly mounted to the firewall. The Connect & Cruise LS was prepped with a host of performance upgrades and fitment modifications.

Day Three

The 1985 C10 was still up in the air by the end of Day 3. But, the crew completed the drivetrain install minus the driveshaft.Next they routed and connected all the engine and transmission control harness wiring. More miscellaneous wiring for lighting and accessories followed. The remainder of the C10’s wiring focused on a complete vehicle harness kit.

Day Four

Yet again, wiring continued. Day 4 saw more wiring in the cab with the guys finalizing the electronics from front to rear. Then. connections were completed for the fuel system in the engine bay, gauges in the dash, and modern LED lighting all around. Next, the CPP Classic Fit Steering Column with 5-Way adjustable tilt was installed. This added some creature comfort to the cab, and was topped with a billet aluminum steering wheel for a custom touch.

Day Five

The last day was spent finishing all the odds and ends before firing up the 525 horsepower LS under the hood. With the driveshaft connected and engine filled with fluids, the Classic Performance Products crew was back to bleed the CPP four-wheel Big Brake disc brakes. The Square Body Chevy was sure to work like a charm, boosted with a CPP Street Beast HydraStop hydraulic assist brake system. Day 5 was coming to a close, but still handed the crew a few snags while firing the engine. The crew stuck through it, pinpointed the problems, and ended the night’s performance with bellows of smokey burnouts!

Want to see and read even more? Check out the full build page on the 1985 C10 Square Body Chevy!