As seen in the June/July 2020 issue of Classic Truck Performance magazine!

Text and Photos by Rob Fortier

You may be a purist at heart—and bless that heart of yours if so—but no matter what your beliefs are when it comes to vintage truck mechanicals such as brakes, if you live and drive in any metropolitan area where there’s more than just one major intersection slash stop sign, and you still drive a four-wheel drum-brake equipped pickup—bless more than just that heart of yours! It’s time to rethink those basic principles and step your brake game up a notch!

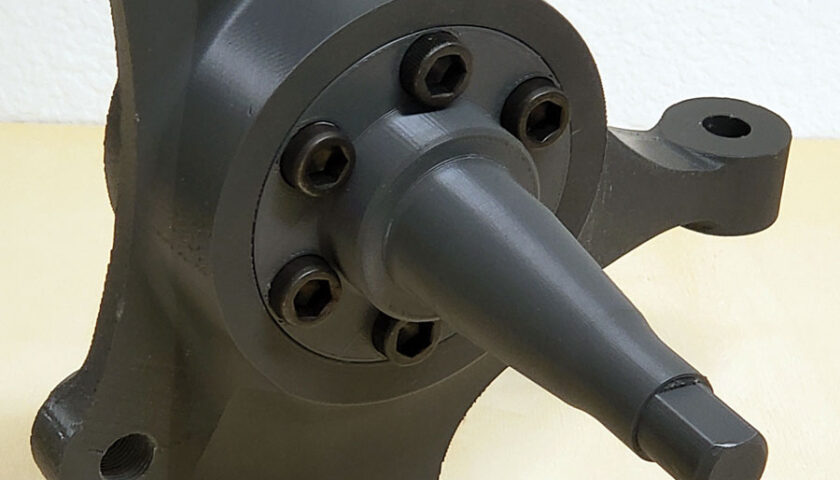

When it comes to the mid-‘60s generation of Ford F100s, twin I-beam owners can rejoice if they’re ready and willing to upgrade their choice of front brakes thanks to Classic Performance Products. CPP manufactures two spindle upgrade options for the ’65-72 half-tons: an OE Stock Spindle (all-new cast ductile iron, not repurposed ’73-79 disc brake spindles) with integrated caliper mount and their Modular Spindle with bolt-on mounts that allow the use of either 12- or 13-inch brake packages (the OE reproduction spindle uses a reproduction 12-inch Ford brake package). Both come with new king pins and bushings pre-installed (yes, you don’t have to worry about finding a reamer, let alone using one!), making installation much easier than it used to be—not to mention ensuring your truck is equipped with safer, more efficient front brakes.

It’s been some time since I’ve messed around with early Ford axles, so the following “dual-purpose” install actually served as a nice refresher course for myself as well!

(As a side note, if you’re looking for the extreme king pin spindle and brake performance upgrade for your ’65-72 F100, CPP is about to release their latest offering of Modular dropped spindles: the F-Drop Modular Spindle—the aftermarket’s first ever two-piece modular design 2-inch drop king pin spindle for the F100 twin I-beam!)

Even though we’re not keeping any of the aforementioned components, after the brakes have been removed, you’ll want to take extra caution when driving the old king pins out, as you don’t want to damage the one component that will remain: your axle! (Mushrooming the top of the pin can and will cause you and your axle all kinds of headaches—use a good penetrating oil and/or add heat to help free the pin.)

After the axle’s been thoroughly cleaned and inspected, load the new OE Stock with the supplied bearing on the bottom, shims on top, and slide onto the axle (if it needs to be forced on, remove a shim; if it goes on too easy, add a shim). With the new king pin coated with grease, align the steering stop notch and insert into the spindle (which comes with pre-installed bushings!).

Lock the king pin in place by installing the steering stop—then check the spindle for excess play (if any can be felt, you will definitely need to add shims.) Finish off the spindle by installing the new seal and nut.

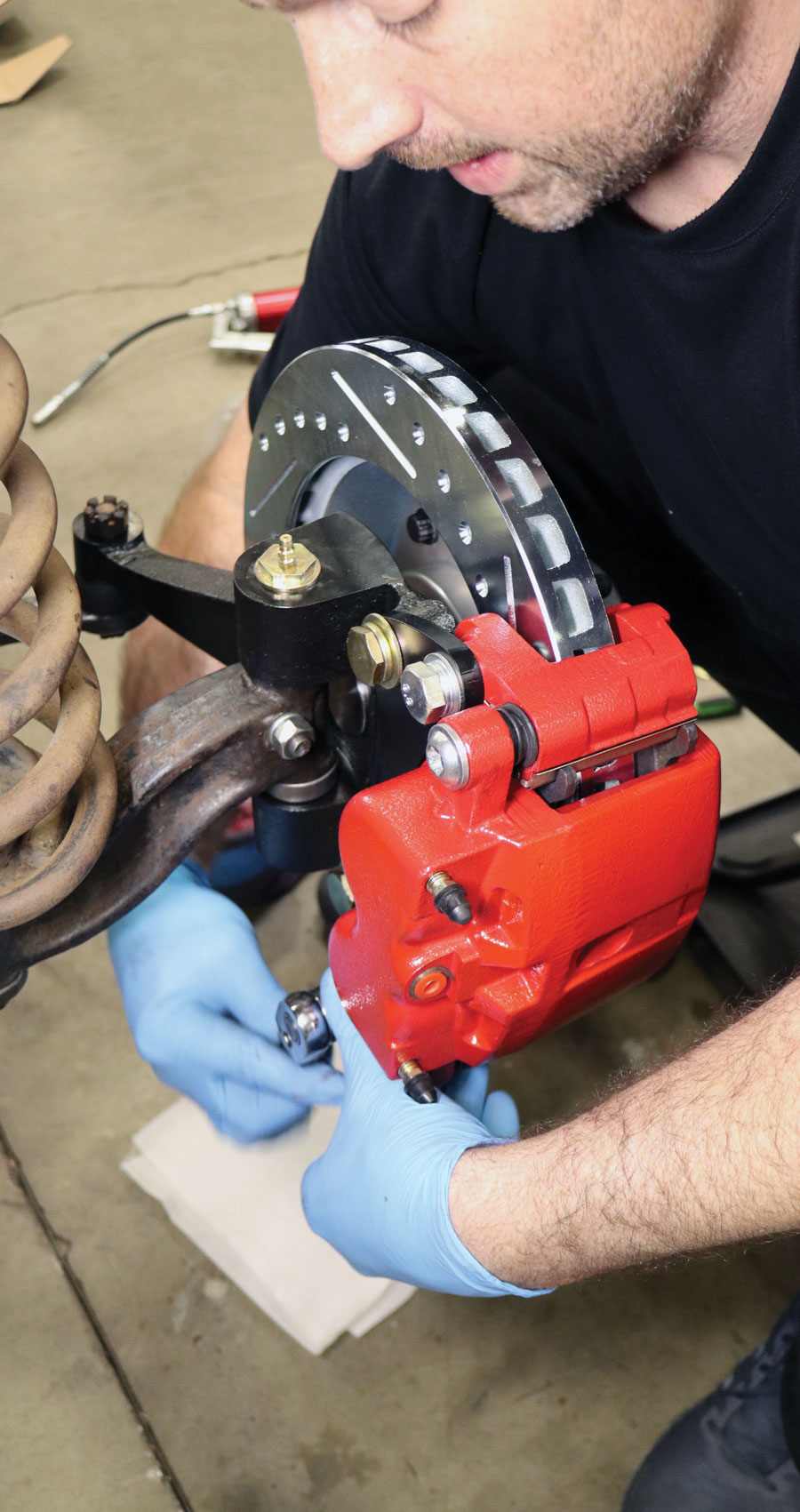

Now, if you thought that was straightforward and simple enough—the brake portion is even simpler. Just load the rotors up with freshly greased bearings, install the rear dust seal, and slide them onto the new spindles and set your bearing preload.

With the bleeder screw on top, install the caliper with the supplied lock plate and spring. When tightening the flange-head bolt, keep in mind that it’s tapered below the flange—that’s why it may appear to be bottoming out (it’s not).

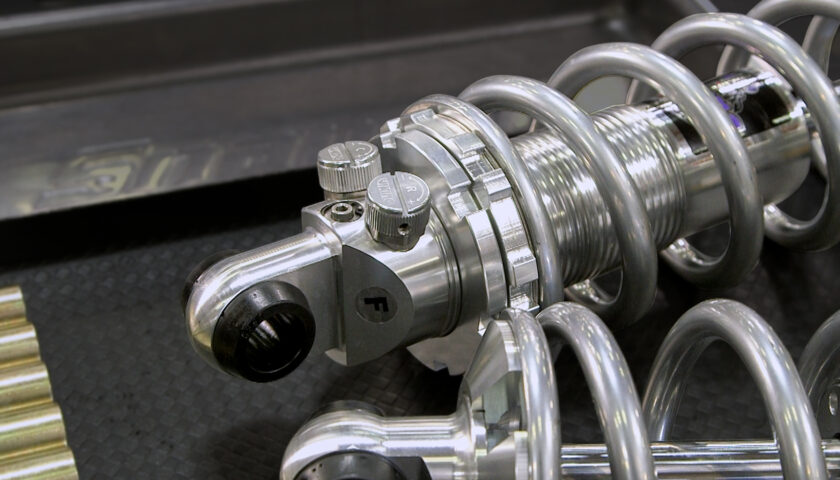

Installation process is the same as the OE’s—ensure there’s no excess play once the king pins are installed before moving on to the brake portion. Also, for added “component stability” when working with the larger brakes, connect the steering linkage to help keep the spindle from flopping back and forth.

Install the hubs just as you would a one-piece rotor as we previously illustrated: pack bearings with grease, install with rear dust seal, and set you preload.

Set the new rotor onto the hub and temporarily secure with a couple lug nut, then hang the new caliper in place—which you’ll notice is forward of the axle rather than behind due to steering linkage interference with the larger caliper (longer braided stainless brake hose is provided to accommodate).